Impression et dépose d'étiquettes sur caisses

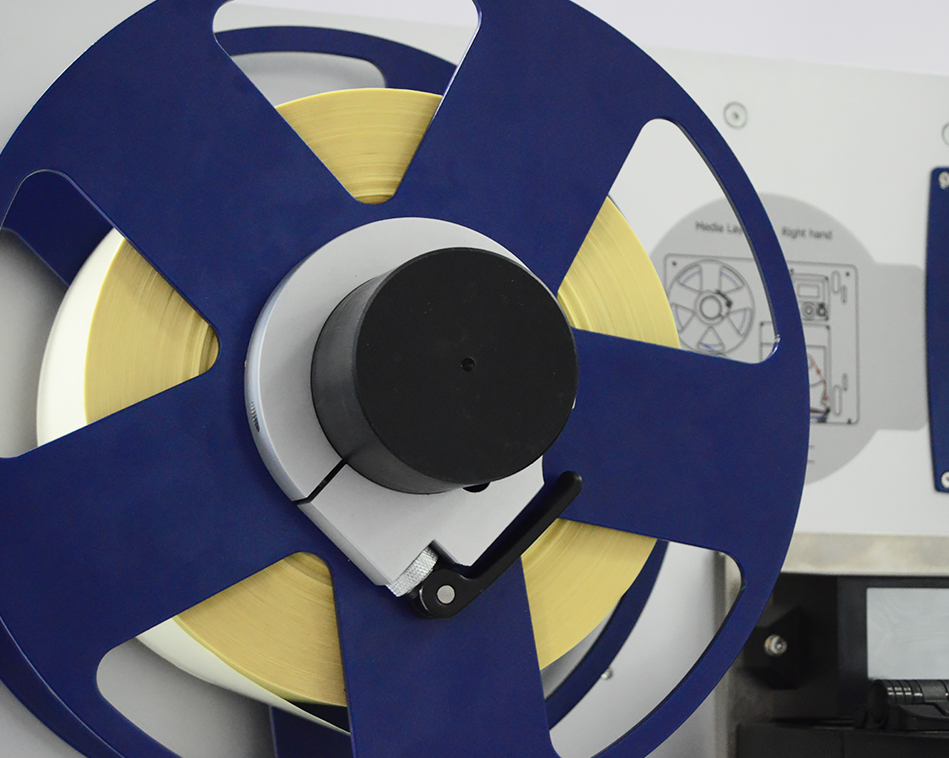

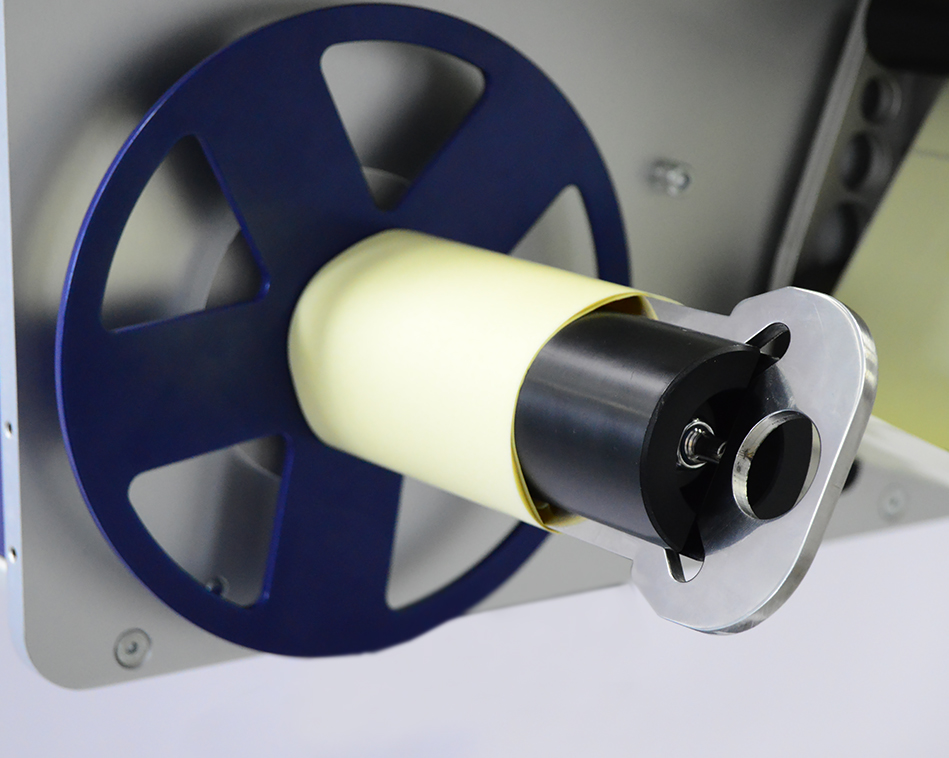

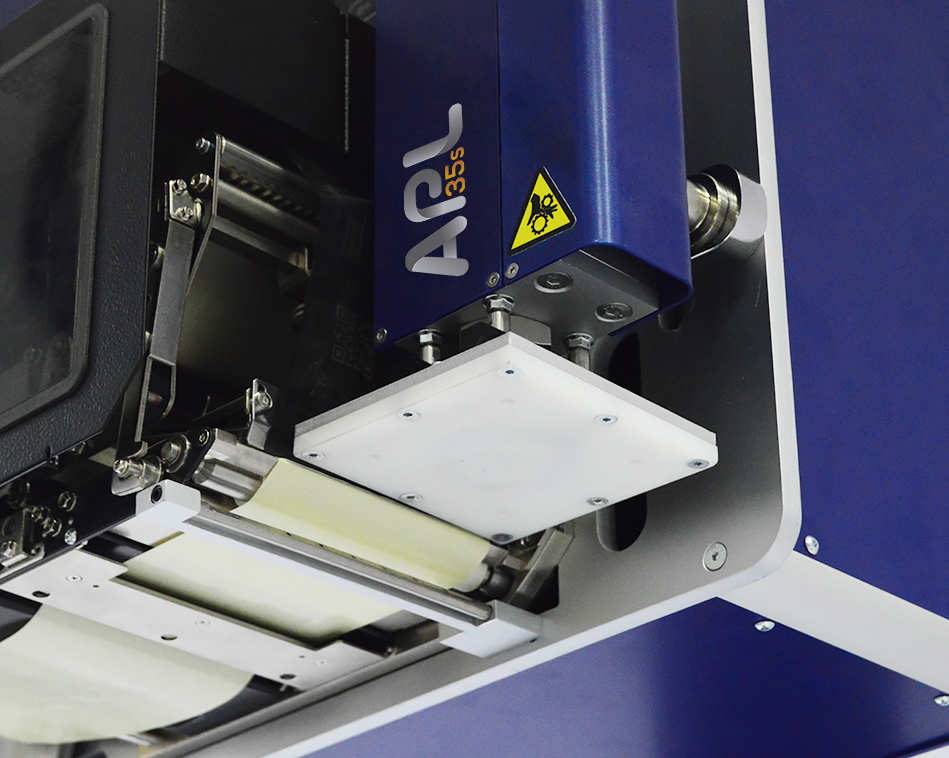

APL35s et 35si

Sys-tème automatique d'impression et dépose d'étiquettes, technologiquement conçu pour répondre aux exigences les plus élevées de l'étiquetage industriel en temps réel sur les lignes de production.

Les imprimantes d'étiquettes APL 35s offrent une large capacité de connexion à tout système d'informa-tion ou d'automatisation, grâce à notre logiciel UBS LabMan 4.0 qui permet la gestion et la connexion des données avec tout système ERP, MES, WMS ou DBMS.

Il dispose d'un tableau de control avec écran tactile pour configurer les paramètres de l'équipement.

L'APL 35s répond aux normes mondiales de codage et de traçabilité GS1 avec l'impression de codes à barres ANSI, grade A et B sur les codes GTIN.

CARACTÉRISTIQUES TECHNIQUES